NIFTI BY DEFENCE INNOVATIONS

Background

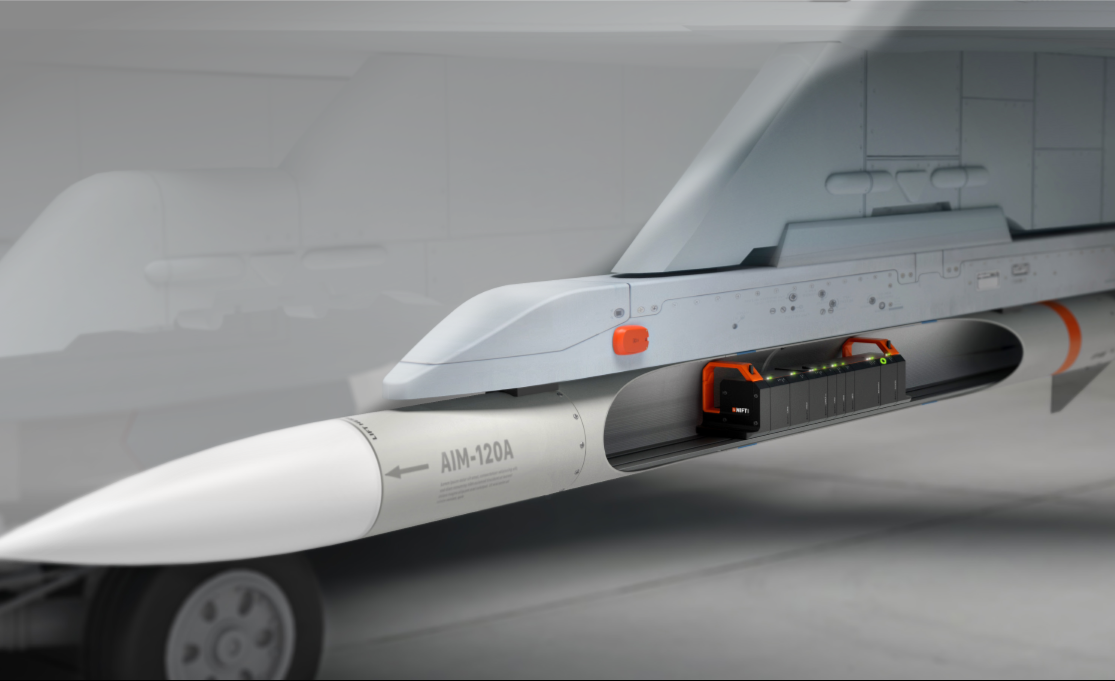

Non-Intrusive Flight Test Instrumentation or NIFTI for short was developed to improve agility and reduce costs involved in the testing of military aircraft.

Systems currently used in aircraft instrumentation are extremely intrusive and time-consuming to install. In many circumstances, an aircraft has to be taken apart panel by panel, and kilometres of wiring installed, connecting hundreds of sensors to a data logger to record the aircraft’s performance.

Defence Innovations wanted to build a product that resolved these fundamental issues and revolutionised the way flight testing was done.

Complete Solution

DESIGN. DEVELOPMENT. ENGINEERING.

Challenge

The challenge was to develop a new test instrumentation system that could make the installation process simple and cost effective while still providing highly accurate synchronised data.

An added challenge was that the configuration of the system and monitoring of sensor data needed to be in real-time and streamed live to the aircraft cockpit. In fact, all system communications needed to be made over wireless without data loss.

The challenges with the current testing approach include:

1) Wires become a factor in the results due to their weight

2) Installation requires modifications to the aircraft

3) Data is processed after the test flight

4) It takes considerable time (and cost) to install and remove the wiring and sensors.

5) Environmental factors: extreme temperatures (-45°C), supersonic speeds, high vibrations, and high G envelopes

Solution

Advisory Services

Initial workshops were undertaken to understand the needs of the RAAF and develop a comprehensive set of requirements and use cases that could be used during development. Development of sketches and refined concepts to begin to understand the limitations, and gain end user feedback.

Other services included:

- Stakeholder Workshops

- User App. wireframe development

- Operational policies and constrains

- Detailed set of requirements

- Development program plan

Engineering Services

The NIFTI system is a modular design that allows the flight test crew to configure and manage the system using an intuitive touchscreen interface. The flight test pilot has complete control of the end-to-end system from the cockpit and can set safety limits and view all sensor data in real-time.

The system is capable of being used at high altitudes and supersonic speeds with no data loss. The proprietary wireless system allows for non-intrusive installation of sensors on internal and external surfaces (i.e. wings) allowing a full system to be installed and configured in under 4 hours!

Key Areas

- MIL-STD-461G Military standard

- Calibrated vibration & strain sensors

- Proprietary wireless

- Sensor synchronisation to ±500uS

- App for flight test management

- Adhesive technologies

PROJECT SUCCESS

Outcome

The NIFTI system was successfully tested on an FA18 travelling supersonic and streaming live data from multiple sensors. It was officially handed over to the Royal Australian Air Force (RAAF) at SCINDICATE2018 in a ceremony officiated by Hon. Christopher Pyne, Minister of Defence.

NIFTI has been praised for its user-friendly installation process, intuitive features, and seamless performance. The accompanying app allows for ease of delegation, configuration, real-time monitoring and an alert system for issue management during flight test.

The NIFTI system has the potential to be applied to other military platforms in the future and has the potential to revolutionise the way flight test is conducted on a global scale.