SENTRY BY AFSTC

Background

Businesses operating commercial refrigeration for the storage of food must act in compliance with Food Safety Standards. In the past this meant manual monitoring and reporting of temperature measurements by staff whose time could be better spent elsewhere. An added complication would often be an expensive loss of stock should any refrigeration unit develop a fault. AFSTC wanted to change this situation by creating the Sentry product, a system to remotely monitor and report the temperature of fridges and freezers in commercial environments. Using sensors and wireless technologies, Sentry eliminates manual work through automated delivery of timed reports, and the provision of alerts when temperatures deviate outside a given range so action can be taken to prevent stock loss.

Complete Solution

DESIGN. DEVELOPMENT. ENGINEERING.

Challenge

Our challenge was to create a wireless sensing and network system that had a 12-month battery life, could withstand -20°C temperatures, and reliably deliver a wireless signal through large metal fridges. The system also needed to be easy to install and configure, and flexible enough for multiple different environments including refrigeration on the go.

Solution

Advisory Services:

At the outset we provided AFSTC with strategic and technology consulting services, including research into the most viable sensor and wireless solutions for their intended application.

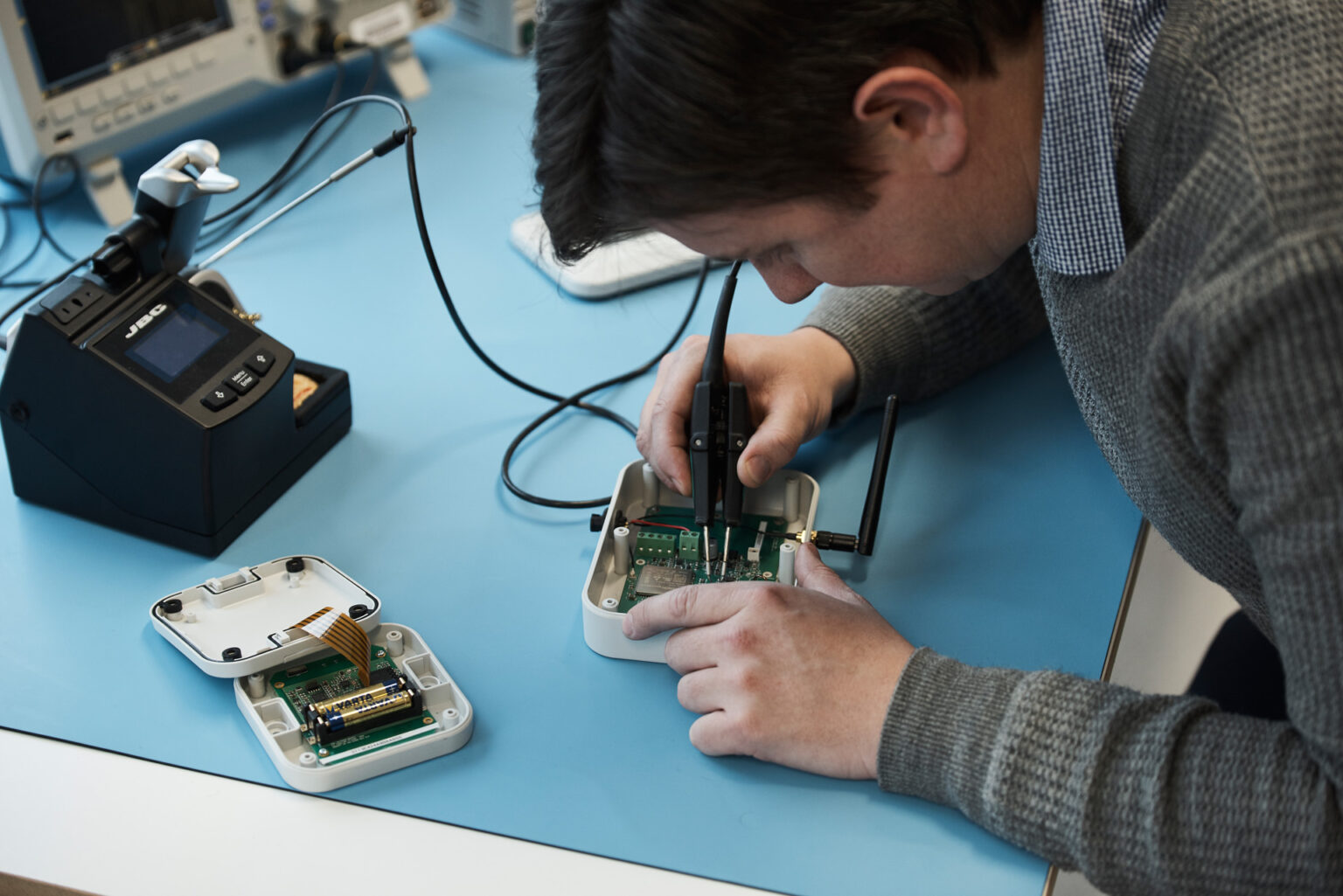

Engineering Services:

We designed a sensor and gateway device that could operate effectively in the harsh conditions of fridges and freezers. We designed battery powered hardware and software that allowed the data collected to be transmitted to the cloud. Sentry also has a web application which delivers alerts and reports to customers on web and mobile, and allows the Sentry team to monitor every installation site.

Manufacturing Services:

Taking the design into manufacturing, we worked closely with a contract manufacturing partner to oversee the set-up of production and to validate the manufacturing process as volume increased.

Key Areas

- Low power wireless network design

- Web portal development

- Reporting to meet HAACP requirements

- Withstanding harsh temperature conditions

- Long battery life

- Low monthly running costs for customers

PROJECT SUCCESS

Outcome

Sentry has given its users confidence that they are compliant with Food Safety Standards, all while reducing the workload on staff. Any issues with refrigeration are known immediately so an expensive loss of stock can be avoided. With 500 installation locations across Australia and the orders flowing through, the AFSTC business is primed for continued growth.